Hemp Paper

Share

The Environmental Problem of Wood-Based Paper

It is well known that wood pulp is the primary raw material for paper production. Today, 42% of all felled trees are used to produce paper — and demand is not decreasing. Earth’s untouched forests are rapidly vanishing, and this problem requires urgent solutions.

Few people know that paper can be made from hemp. Moreover, hemp paper is of higher quality: it is stronger, more durable, and does not yellow over time.

However, there are obstacles to its widespread use. Paper made from wood is cheaper to produce, and the manufacturing process is more technologically advanced.

Yet hemp provides more raw material, and the resulting paper is of a significantly higher class.

Hemp Produces More Raw Material

One hectare of hemp can yield around 6 tons of cellulose per year — significantly more than the annual yield of one hectare of forest.

Trees grow for decades, while hemp can be harvested just 120 days after planting.

Forests require large land areas. Hemp can grow almost anywhere.

Advantages of Hemp Paper

Hemp paper has several important benefits:

- Does not require bleaching

- Does not yellow

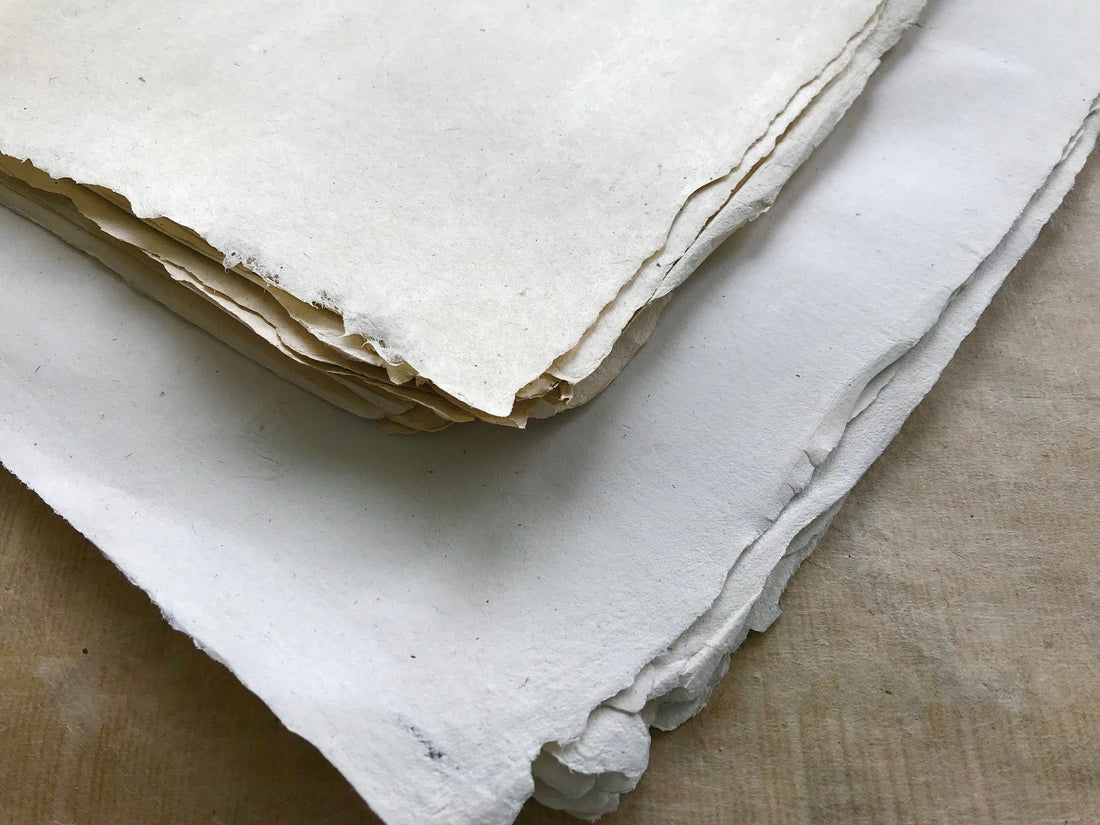

- Stronger and more durable — can last for centuries

- Water-resistant

- Can be recycled multiple times

- Requires fewer chemicals during production

History of Hemp Paper Production

Like many other technologies, hemp papermaking originated in Ancient China. The process included:

- A mixture was prepared from hemp hurds, mulberry bark, old rags, and fishing nets;

- The mixture was boiled until it became a uniform pulp;

- It was then ground to a paste-like consistency;

- Water was added;

- The resulting mixture was filtered through a reed screen, leaving a thin layer of fibrous material;

- The material was laid on smooth boards;

- The boards were stacked and pressed with heavy weight;

- The dried sheets were removed — and paper was ready.

The resulting paper was light, smooth, strong, and elastic. It was very convenient to write on.

The oldest hemp manuscript found in China is over 1,500 years old.

The first paper money, the U.S. Constitution and Declaration of Independence, and Gutenberg's Bible were all printed on hemp paper.

Many historical literary works have survived thanks to the strength and durability of hemp paper.

Why Hemp Lost to Wood

So why did hemp lose the battle with wood pulp?

The answer is simple: the 19th-century industrial revolution and 20th-century capitalism.

The spread of literacy significantly increased the demand for paper. Early industrial paper machines could not process coarse hemp fibers.

There was a need for a simpler and cheaper raw material — and that became wood chips.

In the 1920s, improvements in industrial processing gave hemp a second chance. But the revolution in paper production didn’t happen. A powerful wood-pulp industry had already been established.

At the same time, a massive information campaign began portraying hemp as a dangerous narcotic. As a result, hemp cultivation was severely reduced, and it lost industrial relevance.

The Future of Hemp in Paper Production

Today, the world is witnessing a revival of the hemp industry and a renewed public interest in this unique plant. Increasing restrictions on deforestation are prompting the search for alternative raw materials for paper.

The most critical production problems related to hemp paper have largely been solved. However, to integrate hemp into mainstream paper production, new technologies must be developed to efficiently remove silicates and hemicellulose from the fiber pulp.

Once that hurdle is overcome, modern paper mills could transition to hemp without additional investment in retooling.

Conclusion

Hemp is a sustainable and high-performance alternative to wood in paper production. With further innovation, it has the potential to revolutionize the paper industry while preserving our forests for future generations.